Portable Laser Welding Machines: Features, Cost Factors, and Pricing

Outline and Market Snapshot: How Much Does a Portable Laser Welding Machine Cost?

Before chasing numbers, it helps to map the terrain. Here’s the outline this guide follows, so you can jump to what matters most:

– Core cost drivers that move the sticker price

– A practical price guide by power class and material thickness

– Operating costs and total cost of ownership (TCO) math

– Buying checklist, quoting tips, and alternatives (used, rental, financing)

– Quick-reference scenarios to align budget with results

This outline mirrors the questions fabricators ask when they want handheld laser precision without anchoring a system to one bench.

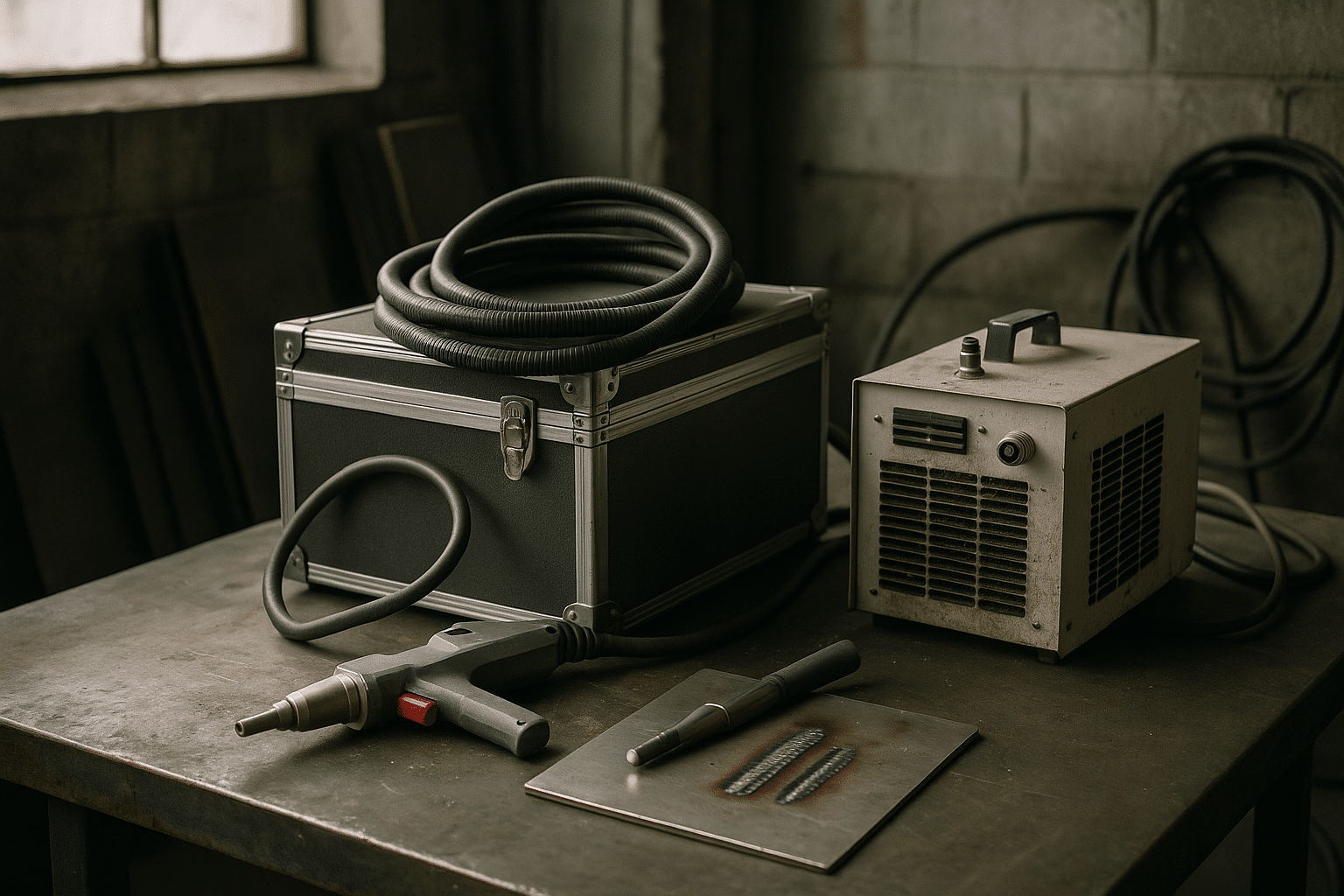

Portable laser welding typically refers to compact, cartable fiber-laser systems with a hand-held gun, integrated or separate chiller, and a small control interface. In today’s market, headline pricing for a basic 1000 W unit can appear as low as about $2,500–$6,000 when advertised without freight, taxes, certification, or robust after‑sales support. For workshop‑ready packages with documented safety accessories, training, and regional compliance, realistic delivered prices often land around $7,000–$12,000 for 1000 W; $9,000–$18,000 for 1500 W; $12,000–$25,000 for 2000 W; and $18,000–$40,000 for 3000 W. Regional labor, warranty structures, and import duties can widen these bands. Expect quotes to look higher from local distributors who bundle onsite service, spare optics, and commissioning.

Why the spread? Laser output power, chiller capacity, beam delivery (wobble heads are popular for gap tolerance), wire feeders, fiber length, and safety provisions all shift cost. Another big swing factor is documentation: electrical conformity, safety interlocks, and laser eyewear with proper optical density add both value and dollars. In brief, the purchase price is just one line: freight, customs, gas supply, and basic training can nudge an “online bargain” into mainstream territory. The goal here is not to upsell you, but to spotlight where the money actually goes so the number on your invoice matches the performance you expect on steel, stainless, or aluminum.

Cost Factors Explained: From Laser Power to Safety Gear

Think of a portable laser welding system as a stack of building blocks. Each block adds capability—and cost. The most visible piece is laser power. For similar feature sets, stepping from 1000 W to 1500 W commonly adds $1,500–$4,000; 1500 W to 2000 W can add another $2,500–$6,000; and 2000 W to 3000 W might add $5,000–$12,000. Power isn’t everything, but it does raise travel speeds and penetration on compatible alloys, especially for stainless and mild steel sheet in the 1–4 mm range. If your work is mostly 0.8–2 mm stainless, 1000–1500 W is often the sweet spot for portability and budget.

Cooling matters almost as much as the laser. Closed-loop chillers sized to the source keep diodes and optics stable. A compact single‑circuit chiller may be bundled at no visible surcharge; higher-capacity or dual‑circuit chillers often add $800–$2,000, and they influence reliability under hot shop conditions or field use. Beam delivery options also affect both quality and price:

– Wobble heads (oscillating beam) improve bridging on small gaps, typically adding $300–$1,200.

– Wire feeders for fillet buildup or gap filling add $400–$1,500 plus consumable wire.

– Extra fiber length (beyond ~10 m) can run $150–$400 per additional meter, trading flexibility for cost and minor handling complexity.

– Protective lenses and nozzles are inexpensive per piece but essential; factor an initial $80–$200 for a small starter kit.

Safety and compliance aren’t just checkboxes. Proper laser eyewear with the right optical density for 1,064 nm wavelengths generally costs $100–$300 per pair. Interlocks, gun-trigger safeguards, and e-stop hardware are expected on reputable units. Documentation—electrical conformity reports, test data, and user training materials—signals a vendor that stands behind the machine; line items for formal training and commissioning may add $300–$1,500 but can reduce scrap and rework on day one. Finally, logistics: crating fees ($100–$250), insured freight ($200–$900 for air or LTL within a region; international freight can be higher), and import duty or VAT where applicable (duty often 0–4%, VAT per local law) are outside the base quote yet very real.

Example build and budget: A 1500 W handheld with wobble head, wire feeder, 12 m fiber, and an upgraded chiller might price at $11,500–$15,500 ex‑works. Add $600 freight and $300 accessories, and the landed cost becomes roughly $12,400–$16,400 before any taxes. Cutting these features can save thousands, but only if the work allows. The right approach is to match features to parts: pay for capability you’ll actually use, not for specs that look impressive but idle on the shelf.

Price Guide by Power Class, Materials, and Typical Jobs

Laser power is the headline, but your parts tell the real story. Below is a practical guide that ties common use cases to typical price ranges for portable units. Numbers reflect delivered, workshop‑ready configurations with basic safety gear; subtract a bit for bare‑bones imports, add for extensive after‑sales and onsite service.

Thin stainless steel (0.5–2.0 mm):

– Suggested class: 1000–1500 W with wobble head for flexibility.

– Typical price range: $7,000–$12,000 (1000 W) or $9,000–$16,000 (1500 W).

– Notes: Shielding with argon or nitrogen at modest flow rates improves bead appearance. Expect travel speeds multiple times those of TIG in lap seams, though joint prep still matters.

General fabrication in mild steel (1–4 mm):

– Suggested class: 1500–2000 W for faster fillets and corner joints.

– Typical price range: $10,000–$18,000 (1500 W) or $12,000–$22,000 (2000 W).

– Notes: Wire feeding helps on outside corners and for gap bridging. For painted parts or contaminated edges, cleaning passes and tighter fit‑up reduce spatter and soot.

Aluminum sheet and extrusions (1–3 mm):

– Suggested class: 1500–2000 W with wobble head and attentive fit‑up.

– Typical price range: $11,000–$20,000.

– Notes: Aluminum reflects more and conducts heat quickly, so travel speed and focus control are important. Nitrogen shielding is common; joint prep and clamping improve repeatability.

Heavier gauge stainless or mild steel (4–6 mm in single‑sided passes):

– Suggested class: 2000–3000 W, recognizing fit‑up becomes more critical and multi‑pass or joint design may be needed.

– Typical price range: $14,000–$30,000+ depending on chiller and optics.

– Notes: For thickness beyond this range, consider joint redesign, backing bars, or non‑portable stations with higher power and fixturing.

Field service and mobile repair:

– Suggested class: 1000–1500 W with rugged case, extended fiber, and stable power source.

– Typical price range: $8,000–$16,000.

– Notes: Emphasize portability: quick‑disconnect lines, strain reliefs, and a chiller that tolerates dust and ambient temperature swings. If operating on generators, confirm steady voltage and surge protection.

Remember that advertised “max thickness” claims can be optimistic. Real productivity depends on joint type, alloy, fit‑up, shielding gas, and operator technique. If in doubt, ask for a sample weld coupon on your actual material and thickness, then request a cross‑section photo or a simple macro‑etch to verify penetration. A grounded price guide tied to your parts will beat any generic spec sheet.

Total Cost of Ownership: Beyond the Sticker Price

Budgeting well means looking past the initial quote. Operating a portable laser welder is relatively lean, but not free. Electricity first: a 1000–1500 W handheld system typically draws around 3–6 kW from the wall under load (laser source, chiller, and controls combined). At $0.12–$0.20 per kWh, that’s roughly $0.36–$1.20 per hour. A 2000 W system may draw 5–8 kW, or $0.60–$1.60 per hour at the same energy rates. Duty cycles and real‑world utilization vary, so consider both peak and average draw if your shop rates fluctuate daily.

Shielding gas usually outweighs electricity in hourly cost for many jobs. Typical flows of 10–20 L/min translate to 0.6–1.2 m³ per hour. If a 9 m³ cylinder of nitrogen costs $25–$45 delivered, gas runs around $1.70–$6.00 per hour. Argon, often used for stainless aesthetics, can be pricier. Some operators blend flows or reserve argon for visible seams only, using nitrogen elsewhere to trim costs. Keep regulators and lines leak‑free; a tiny hiss can drain more dollars than you expect.

Consumables and routine maintenance are manageable but should be budgeted:

– Protective lenses: $10–$40 each, with replacement frequency driven by cleanliness and fume exposure.

– Nozzles/ceramic cups: $5–$20 each; plan a small stock.

– Wire filler (if used): $25–$90 per 5–15 lb spool depending on alloy.

– Cleaning supplies and wipes: a few dollars per week.

– Chiller upkeep: periodic fluid checks or replacement; $20–$60 in materials annually, plus minutes not hours of labor when done regularly.

Three‑year TCO snapshot for a mid‑range 1500 W setup:

– Purchase and accessories: $12,000 (machine and chiller), $600 freight, $300 starter consumables → $12,900 landed before tax.

– Annual electricity (6 kW at $0.15 for 800 productive hours): ≈ $720.

– Annual gas (assume $3.00/h blended average, 800 h): ≈ $2,400.

– Annual consumables and service: ≈ $400–$600.

Over three years, operating costs tally around $10,500–$11,500. That puts an indicative three‑year total near $23,000–$24,500 before any taxes, training, or unexpected repairs. If your process replaces slower methods and trims rework, time savings can eclipse these costs quickly. Even conservative productivity gains—say 2–3× faster than some TIG tasks on thin sheet with similar cosmetic quality—can shift the return‑on‑investment timeline from years to months, provided the work is steady and setup practices are sound.

Buying Checklist, Quotes, Alternatives, and ROI Tips

Quotes vary widely, so standardize what you ask for. A good request for quote (RFQ) includes:

– Power class, target materials and thicknesses, typical joint types (lap, fillet, butt), and desired travel speeds.

– Required features (wobble head, wire feeder, fiber length, foot control), plus any portability constraints.

– Safety items (OD‑rated eyewear for 1,064 nm, interlocks, e‑stops), documentation needs, and local compliance.

– Delivery terms (Incoterms), freight method, lead time, training, and warranty response times.

When the quote arrives, decode the fine print. Confirm what “complete” means: chiller included, gun and cables, spare lenses, nozzles, basic tool kit, and any software keys if applicable. Ask for a sample weld on your material and thickness—including photos of bead top and root. Ideally, request a simple macro‑etch image of a cross‑section to verify penetration, especially for aluminum and thicker stainless. Clarify after‑sales support:

– Warranty length and what’s covered (laser source, chiller, optics).

– Remote support hours and typical response time.

– Availability and pricing of spare optics, nozzles, and filters.

– Onsite service options and travel rates.

Alternatives can stretch your budget. Rentals, where available, often run $250–$600 per week for 1000–1500 W class units and are useful for short projects or trials. Quality used machines can come in at 20–40% below new pricing; assess fiber health, chiller condition, and cosmetic clues about care. Financing smooths cash flow, but scrutinize total payback and bundled costs. If you negotiate, focus on value adds rather than chasing a rock‑bottom figure:

– Extra protective lenses and nozzles at no charge.

– A few hours of remote training included.

– Slightly longer fiber or upgraded chiller at the same price.

– A commitment to hold spare parts locally or ship within 24 hours.

Finally, sanity‑check ROI with your own numbers. Multiply estimated time saved per part by your shop rate, subtract incremental OPEX (electricity + gas + consumables), and compare against monthly financing or depreciation. If the math only works under perfect conditions, revisit joint prep, fixturing, and gas strategy; small process tweaks can unlock big gains. Portable laser welding is compelling because it brings precision and speed to places a large cell can’t reach. With a clear-eyed price guide and a disciplined purchase process, you can land a machine that pays its way without surprises.